As industrial automation and robotics continue to advance, the importance of high-quality components, such as valves, becomes increasingly evident. Valves play a critical role in controlling fluid flow and ensuring the optimal functioning of automated systems. This article will explore the role of valves in industrial automation and robotics, focusing on Pneumadyne as a leading provider of high-performance valve solutions.

Valves in Pneumatic Systems

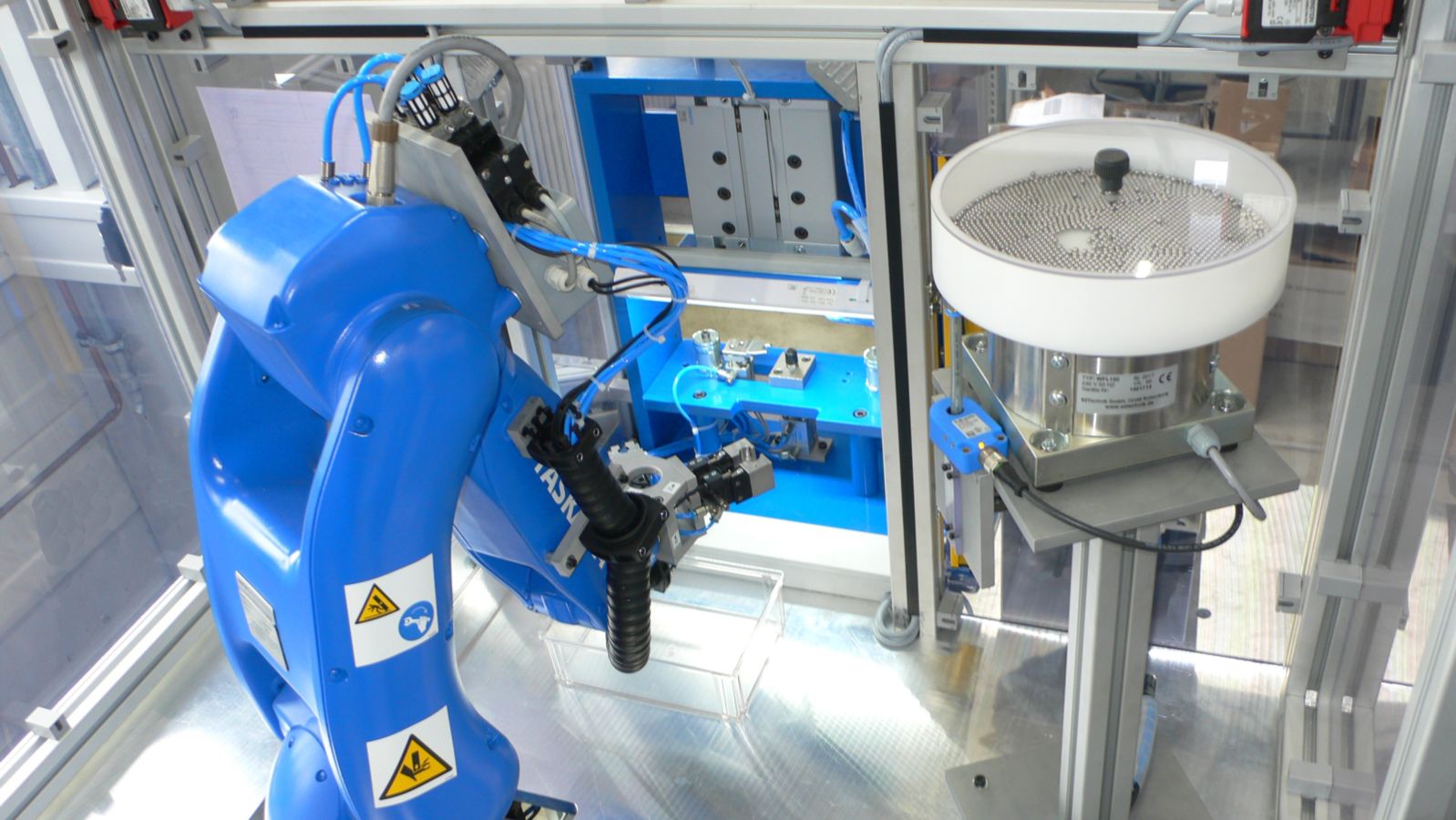

Pneumatic systems are widely used in industrial automation and robotics due to their power, precision, and reliability. Valves, such as those from Pneumadyne, are essential components in these systems, as they regulate airflow and pressure to ensure proper actuation of various robotic elements. From directional control valves to pressure relief valves, selecting the right valve for your application is crucial for maintaining efficiency and performance.

Importance of Valve Performance and Reliability

In automated processes, where productivity and accuracy are paramount, the performance and reliability of valves are crucial. High-quality valves, like Pneumadyne Valve, are designed to withstand the demanding conditions of industrial automation, ensuring consistent performance and minimal downtime. Durable materials, innovative designs, and stringent manufacturing processes all contribute to the reliability and performance of these valves.

Integrating Valves with Automation Controllers

Seamless integration between valves and automation controllers is essential for efficient and precise control in robotics applications. Pneumadyne USA offers a range of solenoid-operated valves that can be easily integrated with programmable logic controllers (PLCs) and other automation systems. This integration enables real-time monitoring and control of valve functions, ensuring optimal performance and responsiveness in dynamic industrial environments.

Valves in Safety and Compliance

In addition to their role in process control, valves also play a critical role in ensuring the safety and compliance of automated systems. Valves such as pressure relief valves and safety shut-off valves protect equipment and personnel by preventing over-pressurization or other potentially hazardous conditions. Pneumadyne's commitment to high-quality valve design and manufacturing ensures that its valves meet the necessary safety standards for various industrial applications.

Selecting the Right Valve for Your Automation Project

When choosing valves for your industrial automation or robotics project, it is crucial to consider factors such as the type of valve, material compatibility, flow rate, and pressure requirements. Pneumadyne offers a comprehensive range of valve solutions to meet the diverse needs of various applications, ensuring that you can find the perfect valve for your specific project.

The Bottom Line

Valves play an essential role in industrial automation and robotics, providing precise control and ensuring the safety and reliability of these systems. High-quality valves offer the performance, durability, and innovation needed to meet the demands of modern robotics applications. By selecting the right valve solution for your project, you can optimize the efficiency and performance of your automated systems. For top-quality valves and other essential components for your automation project, consider DAS Services, as they provide the best Pneumadyne valves and other high-performance solutions for your automation and robotics needs. For more information, visit this website- Dasservicesinc.com.