Copper

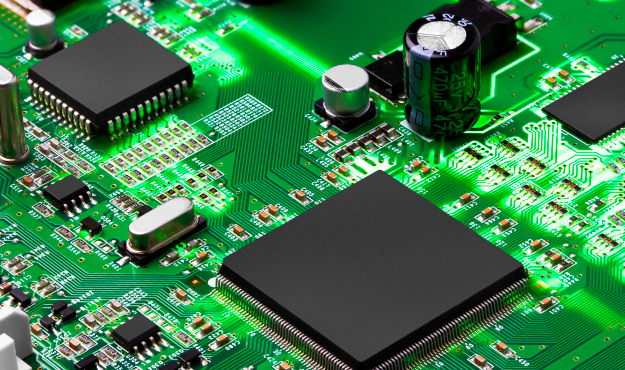

Due to its high electrical conductivity, copper is the most used engaging in material for circuitry in PCBs. The laminates defined above, all come with skinny sheets of copper foil laminated to at least one or each aspects of the plastic. The fabricator then makes use of the gerber files provided by way of the fashion designer, to photo and etch the circuits to meet the purchaser’s requirements. The thickness and wide variety of layers required are largely established upon the application for which the PCB could be used. Multi-layered PCBs are constructed with the aid of alternating layers of copper circuitry and insulating substances to complete the PCB.

Soldermask

Soldermask is a liquid, normally an epoxy fabric, this is implemented onto the outerlayers of rigid PCBs. It is also commonly used on the inflexible sections of inflexible flex PCB’s. Soldermask is in general designed to insulate the copper circuits on outerlayers from oxidation from the surroundings. Soldermask is also designed to manipulate and preserve the waft of solder whilst the components are assembled to the PCB. Without soldermask, the liquid solder could flow out onto the floor of the PCB, connecting two adjacent circuits and brief out the board. The maximum not unusual colour for soldermask is inexperienced, but blue, black, purple, amber, clean, white and plenty of other colours exist as nicely.

Nomenclature

Once the soldermask layers are finished, figuring out records, marks and from time to time bar codes, are published onto the soldermask. These marks are known as nomenclature, and they will additionally be described by means of files that had been protected with the alternative gerber layers. They are published onto the solder mask to help guarantee accurate meeting of the PCB.

Printed Circuit Board Design

PCBs are available a ramification of designs, so it is essential to have a radical information of the layout technique. Some of the important thing factors to remember when designing a PCB include:

Application for which the PCB might be used

Environment wherein the PCB will function

Amount of space and configuration required for set up

Flexibility of the PCB

Installation and meeting

Selecting the right PCB layout to healthy these concerns appreciably affects manufacturability, production pace, product yield, operation fees, and lead instances.

For greater insights into the design system – specially for inflexible flex systems, which we describe further down this web page – down load our free Rigid-Flex PCB Application & Design Guide.

We have additionally acquired UL ninety four V-zero qualification for rigid-flex and flexible circuits, with the most important list of UL rankings for rigid flex international. So, your forums can be ninety four V-zero certified with out additional testing (accordingly expediting the fabrication and delivery of our PCBs). For greater records at the significance of UL qualification for rigid-flex PCBs, see our white paper “The Problem With UL Approval of Rigid-Flex Circuits”.